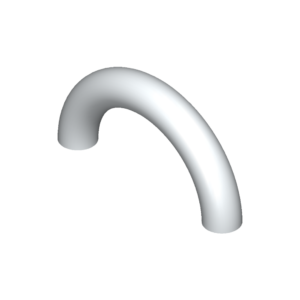

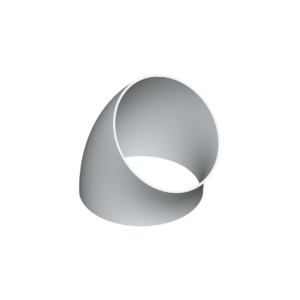

Aluminum, copper and copper-nickel elbows

Jakob Hülsen GmbH & Co. KG has elbows made of aluminum, copper and copper-nickel in different designs acc. to ASTM B361, DIN 2605 and DIN 2607, DIN 86090 in its product portfolio. Due to the different properties, the elbows are used, for example, in shipbuilding, in plant and apparatus engineering, in tanker vehicle construction, in the area of heating and sanitary systems as well as in the area of plant engineering in general.

Get to know our different products in the field of bows: